custom shaped and bonded Special clear acrylic Tubes and Hoppers

This is the ultimate goal for transparent plastics like PLEXIGLAS® / acrylic glass or EXOLON® GP made of MAKROLON® / polycarbonate: Machine and equipment users often prefer the possibility of visual process monitoring without having to interrupt production and deal with downtimes. There is a wide range of possibilities when it comes to design solutions: The easiest approach is to use individual PLEXIGLAS® / acrylic glass tubes to monitor the flow of liquids. With HECKER®, these plexiglass tubes / acrylic glass tubes can also be custom manufactured with special diameters and virtually invisible bond seams. Custom PLEXIGLAS® / acrylic glass hoppers for monitoring bulk goods or filling powdery substances like coffee grounds are also popular.

This photo shows the “Munksjö bridge” in Southern Sweden built by one of Europe’s leading structural engineering firms. The 10 pieces on the tip of the masts are brilliant transparent HECKER® special tubes made of PLEXIGLAS® / acrylic glass (dimensions: outer 711 Ø mm, length 2,900 mm, 10 mm wall thickness) and were made with two hot formed and subsequently CNC routed half-tubes with two longitudinal joints bonded together invisibly. PLEXIGLAS® / acrylic glass tubes are used as the crowning point on pylons that are illuminated with alternating colours.

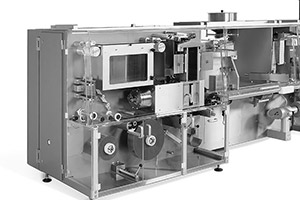

Protective Shielding for Machinery

Protective Shielding for Machinery Medical & Lab Technology

Medical & Lab Technology Functional and Simulation Models

Functional and Simulation Models Special Tubes and Hoppers

Special Tubes and Hoppers Plastics Technology

Plastics Technology Surface Finishing

Surface Finishing